Your cart is empty

Regulatory Compliant PTFE Additives for Greases and Lubricants

Posted by Shamrock Technical Service Group on 7/20/2020

© Copyright 2020, Shamrock Technologies, Inc. All Rights Reserved.

Polytetrafluoroethylene (PTFE) micro-powders are inert, low molecular weight (MW) white powders with finely controlled particle sizes that range from sub-micron to several microns. These fine powders retain the unique properties of the longer chain, higher molecular weight homologues of PTFE resin, imparting specific benefits like lubricity, high wear resistance and ability to thicken oils and greases, across a wide range of temperatures, from -190℃ to 260℃. They are insoluble in water and in all common solvents and exhibit great weathering and ageing properties. Given the low inherent Coefficient of Friction (CoF), these amazing powders help to improve surface lubricity in coatings, enabling its wide use in non-stick applications as well as providing unparalleled boundary layer lubrication.

PTFE resin is made by polymerizing tetrafluoroethylene (TFE) monomer to very high molecular weight, in the millions. Most PTFE micro-powders are made by the degradation of such high MW PTFE resin. Degradation may be affected by thermal or radiation induced processes, leading to the scission of the backbone carbon-carbon bonds to form active free radicals. In such degradation processes, there is a random distribution of varying chain lengths, and a very small amount of the molecules may be 8 carbons long. The 8-carbon radical can combine with oxygen and moisture in the air to form a terminal carboxylic acid group, resulting in Per-Fluoro-Octanoic Acid (PFOA). The concentration of PFOA in the degradative process of making PTFE micro-powders may be in the range of parts per million. Thus, it is necessary to ensure a post-treatment process to remove the incidental PFOA, regardless of degradation process, be it thermal, or ionizing radiation, to be compliant with evolving European environmental regulations.

The European Chemicals Agency had put forth conditions of restriction as published in Entry 68 of Annex XVII to REACH, requiring a limitation of no more than 25 parts per billion (grams per thousand tons) of PFOA in PTFE micro-powder to take effect on 4 July, 2020. In this transitional 2-year derogation, PTFE micro-powders need to be tested and, if necessary, treated to ensure the content of PFOA and its salts are less than 1000 parts per billion under the exemption.

As of this time, there is no globally accepted standard test method for measuring PFOA content in PTFE micro-powders. Shamrock pro-actively developed a test method based on extraction of PTFE powders with methanol and the use of Liquid chromatography-mass spectrometry (LC-MS) to determine the concentration of PFOA. Shamrock’s internal Test Method, QSOP-202E[ii], has correlated well with test data (of the same powder samples) from external test centers to validate accuracy and precision. Scientists generally agree that an accepted test method is based on calibration with known standards, and test results of the same samples in different labs must be within experimental error.

With a validated Test Method, Shamrock established a fully dedicated PFOA Test Center with 2 LC-MS systems and started building the database of PFOA content in its portfolio of PTFE-containing products. With statistically significant lot-verified data, Shamrock mapped out pathways ensuring that its product lines are Regulatory Compliant (RC) with the EU restrictions on PFOA on an industrial scale, product by product, and lot by lot.

PTFE micro-powders based on controlled degradation processes may be made with virgin or recycled based PTFE. The virgin PTFE tends to be softer, unprocessed material that offers a more controlled starting morphology and MW, along with a higher cost. PTFE virgin resin is however costly to make, from an environmental and ecological perspective, as it emits approximately 10 kg of carbon dioxide (CO2) for every kg of new resin being made [iii]. Recycled PTFE tends to be a somewhat harder, lower cost material, but more importantly, the use of recycled material not only prevents the persistent, non-biodegradable material from ending up in landfills, but also prevents the high CO2 emissions relative to the use of virgin feedstocks.

In some applications, the recycled based PTFE micro-powder products out-perform virgin based products, and in others, the opposite. Different degrees of degradation seem to work better in some specific applications. Combinations of raw material type and varying degrees of degradation result in different pathways to achieve the desired RC product with similar performance to the original non-RC version. PTFE micro-powders are used in diverse industries for a wide range of performance properties. In grease and lubricant application, they are used both as thickening and anti-wear additives for extreme pressure (EP) formulations. The following are illustrations of how the RC PTFE micro-powders perform relative to the already established non-RC versions.

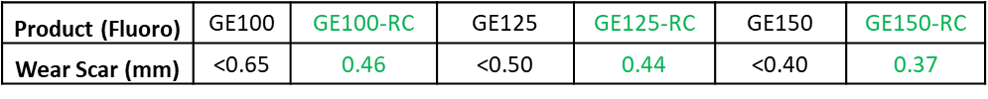

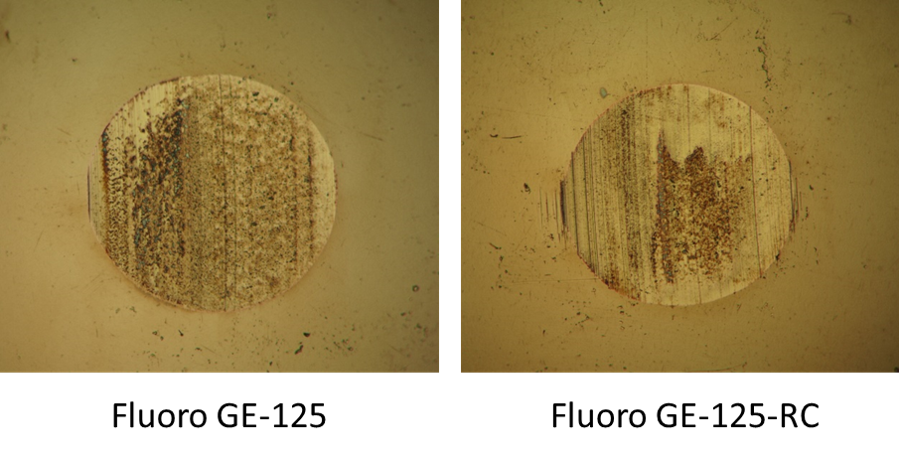

In the 4 Ball Wear tests a polyalphaolefin (PAO 6) base oil was thickened with 50% PTFE micro-powder and wear scars were compared.

In EP tests, a polyalphaolefin (PAO 6) base oil was thickened with various PTFE micro-powders to a National Lubricating Grease Institute (NLGI) #2 grease consistency.

As evident from the above test data, and with customer validated production-based conversions across multiple industries, Shamrock has successfully transitioned the major products in our current PTFE micro-powder portfolio towards Regulatory Compliance, and have been shipping these lot-verified RC products globally. Contact our Marketing REACH Compliance team to explore the possibilities at MRC@shamrocktechnologies.com.

Contact us if you have any questions or more information regarding our Shamrock Regulatory Compliant PTFE products.

Click here to find information regarding our test method QSOP-202E.

[i] ECHA. “REGULATION (EU) 2019/1021 OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 20 June 2019 on Persistent Organic Pollutants.” EUR-LEX, 25 June 2019, eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32019R1021&from=EN.

[ii] Chen, Bin. “QSOP – 202E.” Shamrock Technologies, 15 Jan. 2020, https://shamrocktechnologies.com/research/#QSOP202E

[iii] Poszmik, G., Kim, HS., and Choo, J. “Estimating the Impact of Using Recycled PTFE on CO2 Emissions.” Shamrock Technologies, 14 July 2020, https://shamrocktechnologies.com/co2-emissions/

Addendum:

The EU has added C9-C14 PFCAs and C9-C14 PFCA-related substances under ANNEX XVII of REACH. The new law will become effective on February 25, 2023.

On August 5, 2021, the European Union (EU) published Regulation (EU) 2021/1297 to replace entry 68 to Annex XVII of Regulation (EC) 1907/2006 on Registration, Evaluation, Authorization and Restriction of Chemicals (REACH, consolidated version to July 2021) in relation to ‘Restrictions on the manufacturing, placing on the market and use of certain dangerous substances, mixtures and articles.’