Your cart is empty

Texturing Powders for Inks and Coatings

Ink and Texture Coating: High Molecular Weight Polyolefins (HMWPE)

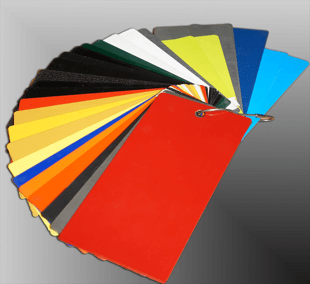

Shamrock Technologies offers a variety of texturing additives to provide the perfect combination of texture and compatibility. Powder texture additives add ink texture and give texture to coatings.

Benefits of Texture Power Additives

Different texture additives offer different types of effects and benefits.

- Decorative appearance

- Anti-skid

- Matting

- Feel / hapticity

- Water repellency

- Abrasion resistance

Ink and Texture Coating: High Molecular Weight Polyolefins (HMWPE)

For air-dry and Baked Coatings requiring nonskid or high COF, smooth or soft feel, and mar / abrasion resistance, we recommend the use of High Molecular Weight PE. This textured coating additive is best for Screen inks, Decorative, General Industrial, and Coil Coatings.

| Product | Particle Size Mean Value | DSC Melt Point |

|---|---|---|

| TEXTURE ULTRA FINE | 35 µm | 144ºC |

| TEXTURE 5378 WHITE | 50 µm | 144ºC |

| TEXTURE 5380 WHITE | 65 µm | 144ºC |

| TEXTURE 5382 WHITE | 80 µm | 144ºC |

| TEXTURE 5384 WHITE | 110 µm | 144ºC |

| TEXTURE 5386 WHITE | 150 µm | 144ºC |

| TEXTURE 5388 WHITE | 165 µm | 144ºC |

Texture Coating: Polypropylene (PP)

For air / forced dried coatings requiring Nonskid or high COF, matting, controlled feel and abrasion resistance. Polypropylene is recommended for wood, architectural, plastic and general industrial coatings.

Texture Powder: PowderTex

Sub-micron PTFE particles can be used to create a texturing effect, which allows for very efficient matting and micro-rough feel.

| Product | Bulk Density (gr/l) | Melting Point |

|---|---|---|

| POWDERTEX 61-RC | 325 – 425 g/L | 330 °C |

| POWDERTEX 94-RC | 350 – 550 g/L | 320 °C |

Powder Texture: Polymethylmethacrylate (PMMA)

For air dry and baked coatings requiring smooth/soft feel, slip, matting and scratch / abrasion resistance.

| Product | Particle Size Mean Value | DSC Melt Point |

|---|---|---|

| TEXMATTE 6005 | 7 µm | 260ºC |

| TEXMATTE 6010 | 10 µm | 260ºC |

| TEXMATTE 6014 | 13 µm | 260ºC |

| TEXMATTE 6017 | 19 µm | 260ºC |

| TEXMATTE 6030 | 35 µm | 260ºC |