Your cart is empty

Wax and PTFE Water-based Dispersions, Emulsions and Compounds for Inks and Coatings

Our HydroCER® and AquaFLON® series are engineered to incorporate wax and PTFE in a dispersed form ranging from submicron emulsions to high solid powder dispersions. They are designed to provide maximum handling efficiency with performance properties such as controlled slip, abrasion resistance and release.

Features and Benefits

- Gloss and clarity in coatings and inks are typically not affected by the introduction of a wax emulsion

- Surface protection properties such as abrasion, mar, and scuff resistance without negatively impacting adhesive properties

- Emulsions have improved stability compared to dispersions

- Emulsions have a lower viscosity compared to dispersions

- Mar/Scuff resistance

- Abrasion resistance

- Control coefficient of friction

- Water repellency

- Improve burnish resistance

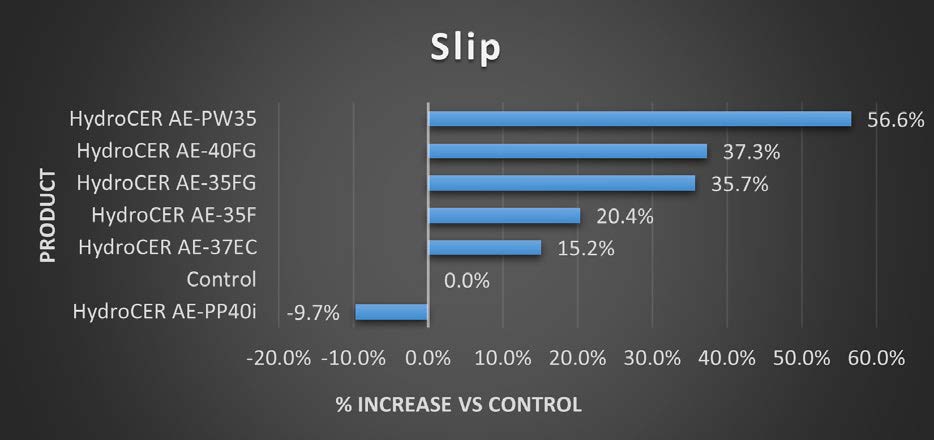

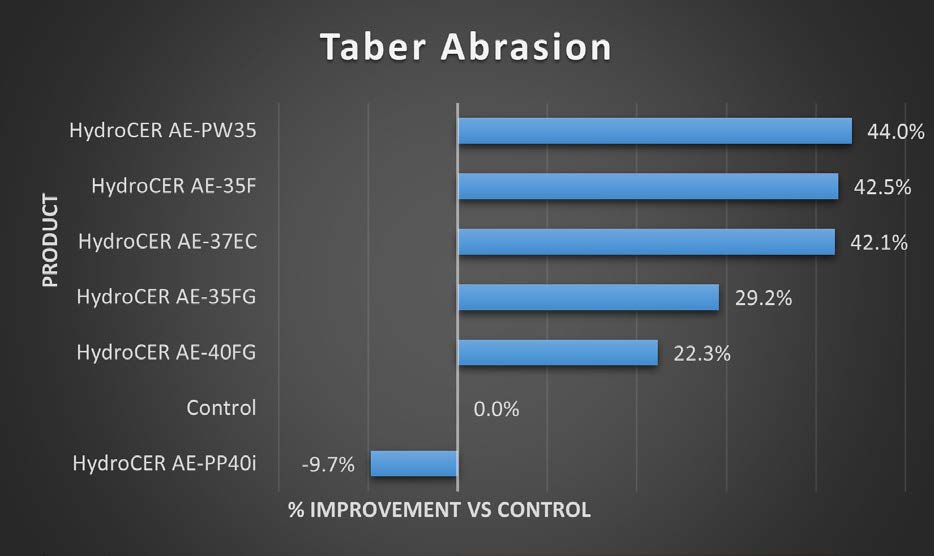

The data in the charts show the effects of the various emulsions that Shamrock Technologies offers when evaluated in a water based polyurethane topcoat. The following testing parameters were followed to generate the data:

A commercial water based polyurethane coating was initially tested without any additions to generate baseline data used to determine the performance benefits of the various wax emulsions.

- When creating the test samples, the various emulsions were post added to the water based polyurethane at the same active wax content. The active wax content was 1.5% of total formula weight.

- Taber abrasion and Coefficient of Friction (COF) testing was run on panels that were allowed to cure for 72 hours, dry film thickness was 0.6 mils.

- Taber abrasion testing was run for 300 cycles using 500 gram weights and CS-10 abrasive wheels.

HydroCER® AE Emulsions

Waxes emulsified in water to sub-micron particle size to accommodate the thinnest films and maintain gloss and clarity

This chart compares the reduction in coefficient of friction, presented in an increase of slip, of the various wax emulsions offered by Shamrock Technologies. Note that our Hydrocer® AE-PP40i shows a decrease in slip versus the control. This product is intended for use in floor coatings where an increase in slip is typically not desired. Hydrocer® AE-PP40i can be used to increase the coefficient of friction when seeking ASTM D2047 compliance.

This chart compares the Taber abrasion resistance of the various wax emulsions that Shamrock offers. All of the emulsions except for Hydrocer® AE-PP40i, show a significant improvement in Taber abrasion resistance vs. the control sample that did not contain a wax emulsion. The small reduction in Taber abrasion resistance observed with the sample containing Hydrocer® AE-PP40i is typical for a wax emulsion that decreases slip as it increases the friction generated between the coating and the abrasive wheels used when running a Taber abrasion test.

Click here to see our Emulsions

Wax Emulsion AdditivesHydroCER® Dispersion

The Hydrocer product line incorporates micronized wax powders from our S-series waxes in a pre-wetted form to provide maximum handling efficiency with performance properties such as controlled slip, abrasion resistance, and release. If these products separate, simple mixing with paddle or propeller mixer, is all that will be required to redisperse.

| Product | Solids % | Weight Per Gallon (lbs./gal.) | Hegman Grind |

|---|---|---|---|

| HydroCER® 135 | 35% | 7.5 – 8.5 lb/gal | 6.0 Min |

| HydroCER® 257 | 45 – 49 % | 8 – 8.4 (lbs./gal.) | 6.5 Min. |

| HydroCER® 303 | 34 – 35 % | 7 – 9 (lbs./gal.) | – |

| HydroCER® 584 | – | 8 lbs. / Gal | – |

HydroCER® Dismulsion®

A blend of aqueous wax emulsions and wax powder

| Product | Solids % | NPIRI Grind | pH | Viscosity |

|---|---|---|---|---|

| HydroCER® D-336 | 33 – 39 % | 5.5 max | 10 – 11 | < 2000 CPS |

| HydroCER® AD-60-ET | 59 – 61% | 2.5 max. | 9 – 10.5 | < 1500 cPS |

AquaFLON® Dispersion

Shamrock’s AquaFLON® series is engineered to overcome the inherent incompatibilities between micronized PTFE and water. Ranging from micron-sized dispersions to sub-micron emulsions, these high solids, ready to use packages provide optimum slip and mar resistance in aqueous systems. They are designed with features optimized for easy incorporation into water-based systems.

| Product | Solids % | Hegman Grind | Weight Per Gallon (lbs./gal.) | pH |

|---|---|---|---|---|

| AquaFLON® 50-RC | 52 – 56 % | 7 Min. | 11.1 – 12.1 (lbs./gal.) | 7 – 9 |

| AquaFLON® 52-RC | 58 – 62 % | 7 | – | 7 – 9 |

| AquaFLON 178G-RC | 50 – 54 % | 6.5 Min. | 9.4 – 9.8 (lbs./gal.) | 8 – 10 |

| AquaFLON® 797-RC | 45 – 49 % | 6 – 7 | 8.1 – 9.1 (lbs./gal.) | 6 – 9 |

| AquaFLON® MG-RC | 47 – 51% | 6 – 7.5 | 8 – 9 (lbs./gal.) | 7 – 10 |

PTFE in Ink Vehicles

FluoroSPERSE® dispersions incorporate high quality PTFE found in our SST series in a variety of heat-set and sheet-fed vehicles, including viscoelastic hydrocarbon varnishes, linseed oil, lithographic oil and soya varnishes. The line is comprised of white or toned PTFE providing exceptional slip, rub resistance, and increased efficiency in high volume, automated printing ink manufacturing processes. FluoroSPERSE dispersions are available in paste or pumpable form.

| Product | % Active | NPIRI Grind |

|---|---|---|

| FluoroSPERSE 966-RC | 58 | 2 Max. |

| FluoroSPERSE 7446-RC | 50 | 2 Max. |

| FluoroSPERSE 7908-RC | 50 | 2.5 Max. |

CeraPERSE® Compounds

Wax compounds are prepared by crystallization of wax from solution to obtain fine particles. Shamrock’s CeraSPERSE® line includes dispersions in hydrocarbon varnish, linseed oil, lithographic oil and soya varnish. They may be added directly into the mixing container. These products provide excellent slip and rub resistance at addition levels of 5-8% based on formulation.

| Product | Composition | Solids % | Carrier | NPIRI Grind | Feature |

|---|---|---|---|---|---|

| CERASPERSE 31 | Carnauba | 18% | Butyl Carbitol | 2 Max. | Slip and scratch resistance |

| CeraSPERSE® 171 | PE | 37 % | Vegetable oil | 2.0 Max. | Slip and rub resistance |

| CeraSPERSE® 174-RC | PE/PTFE | 44 % | Linseed oil | 2 Max. | Combined features from PE and PTFE for enhanced rub resistance, slip and gloss |

| CeraSPERSE®321BG-RC | PE/PTFE/ Carnauba | 25 % | Butyl Carbitol | 2 Max. | Slip and abrasion resistance for High gloss clear applications |